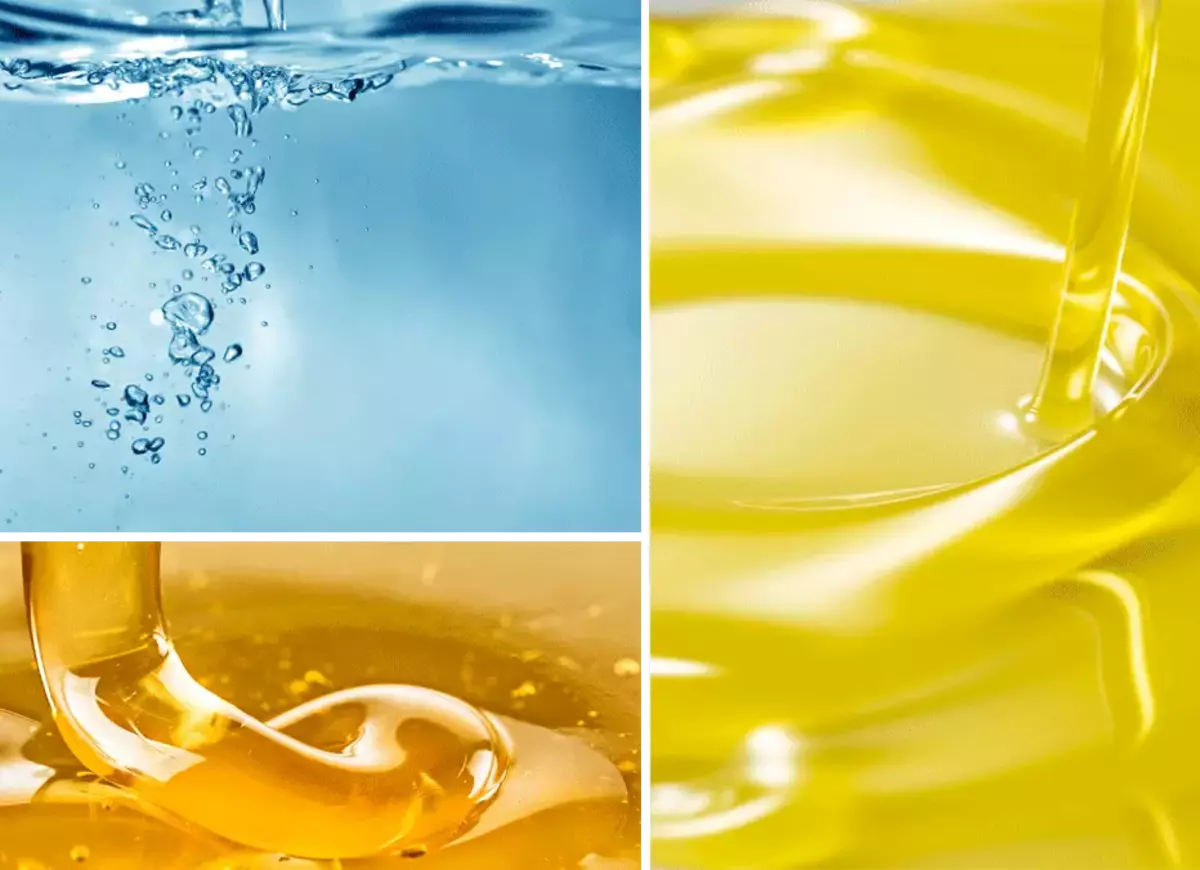

The quantity of liquid to be metered can vary from a few grams to hundreds of kilograms. Special attention must be paid to the specific characteristics of a raw material, because density, viscosity, temperature and reaction behavior can have a considerable influence on the entire dosing process.

DEMIC's control solutions take these factors fully into account. In addition, they support the control of a wide variety of pump types (piston, diaphragm, gear, etc.) and any necessary trace heating. Weighing of the entire dosing system is also included as standard.

All DEMIC control systems stand for precision, effectiveness and durability.

Challenges and solutions in handling pastes & liquids

Challenge ➢ Temperature development

Some raw materials are difficult or impossible to dose and convey due to their viscosity.

The DEMIC-solution:

The control of trace heating is part of the standard repertoire of the control system in liquid metering. In addition, appropriate valve circuits ensure that the material is constantly in motion, thus preventing solidification.

Challenge ➢ Acquisition costs

A formulation usually consists of several components. However, the pumps for the metering processes are sometimes very expensive to purchase. Often, however, one pump is not necessarily required for one raw material.

The DEMIC-solution:

With DEMIC's control solutions, you only need one pump in combination with appropriate valves to be able to draw materials from different containers.

Challenge ➢ Inaccuracy

Flow at increasing flow rates and pressures is not very predictable. In addition, deviations increase due to backflow from the pump and an irregularly filled pump head.

The DEMIC-solution:

All organs involved in the process of dosing, such as pumps and rotary valves, are weighed. By weighing all the equipment, including the fluids, DEMIC controllers provide 100% accuracy in dosing.

Challenge Contamination

When formulating with several pastes and liquids via one pump, contamination quickly occurs and deviations in the formulation occur afterwards.

The DEMIC-solution:

After each dispensing process of a paste or liquid, special cleaning programs can be selected via which the dispensing element, a container and lines are cleaned (e.g. by means of cleaning liquids). In this way, no contamination remains and the subsequent recipes are certainly not falsified.

Would you like to learn more about our products?

We look forward to advising you:

PHONE: +49 2247 918 90

E-MAIL: kontakt(at)demic-datentechnik.de

Your contact

Björn Demmer

Shareholder - General manager

PHONE: +49 2247 918 90

E-MAIL: bdemmer(at)demic-datentechnik.de

Heinz Demmer

Shareholder - General manager

PHONE: +49 2247 918 90

E-MAIL: hdemmer(at)demic-datentechnik.de