CONTROL SYSTEM DE CON /U /BD

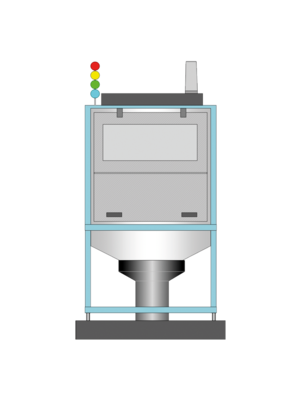

Our DE CON/U/BD control system can be used to control all the processes of classic bag dumpers, with or without recording the filling quantity. Due to the completely Ethernet-based control, you do not need any additional operating devices. The control is web-based and can therefore be controlled from any terminal device.

More about the control system for Bag dumper

Raw material feeds in general, and associated with this also bag dumper, represent a central process engineering unit in many processes. For a long time, these were very simple systems that did not require any control. However, this is increasingly changing due to the ever-increasing requirements for end-to-end process control in the context of Industry 4.0.

New trends in bulk material handling combine bag dumpers with discharge aids or discharge feeders to ensure better and safer discharge of the bulk materials so that the downstream process can run smoothly.

This problem can be solved with the DE-CON/U/BD control system. The completely Ethernet-based control system includes all processes for classic bag dumping with or without recording the filling quantity as standard. The individual program modules are stored in a software library and the various operating modes and parameters can be parameterized quickly and easily via an integrated web server. The web interface can be accessed via notebook, smartphone, tablet or also from the customer's PLC system. A separate operating device for conveying is therefore no longer necessary.

Features

- Time or event-controlled start of extraction and filter cleaning

- Pressure monitoring (negative pressure, positive pressure in suction system, differential pressure across filter)

- Control of discharge aids such as: Oscillating floor, dosing unit, rotary valves

- Level monitoring (min/max)

- Control of closure systems below the bag dumper

- Filling quantity recording and weighing via different types of load cells

- Automatisierte Zuführung von Gebinden

Would you like to learn more about our products?

We look forward to advising you:

PHONE: +49 2247 918 90

E-MAIL: kontakt(at)demic-datentechnik.de

Your contact

Björn Demmer

Shareholder - General manager

PHONE: +49 2247 918 90

E-MAIL: bdemmer(at)demic-datentechnik.de

Heinz Demmer

Shareholder - General manager

PHONE: +49 2247 918 90

E-MAIL: hdemmer(at)demic-datentechnik.de