Conveying & Refilling with DEMIC

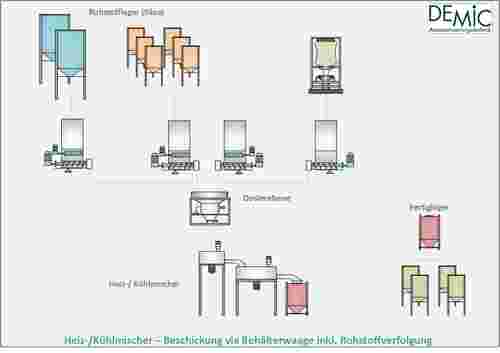

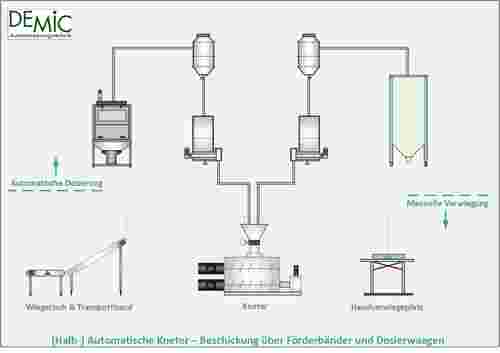

Increasing demands on the feeding of raw materials into the various processes, such as: Mixing, Agglomeration, Homogenization etc., require increasingly powerful control systems for the process elements involved (Big Bag Stations, Bag Pourers, Conveyors and Feeders).

Our decentralized automation solutions combined with a modular component design are suitable for all manufacturers of conveyors and transport systems who bring ready-to-connect components to the market. We customize the entire drive and control technology to your individual processes and requirements and thus ensures a maximum ofobject-oriented planning and project engineering.

Your benefit will be reducing costs and downtimes in your company while increasing your efficiency.

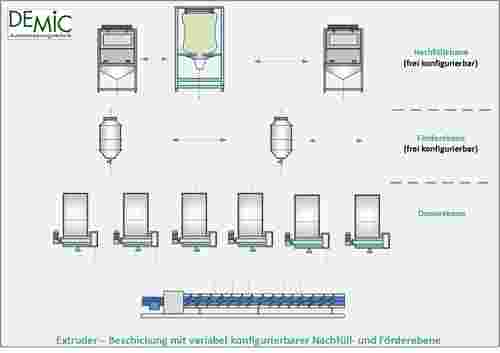

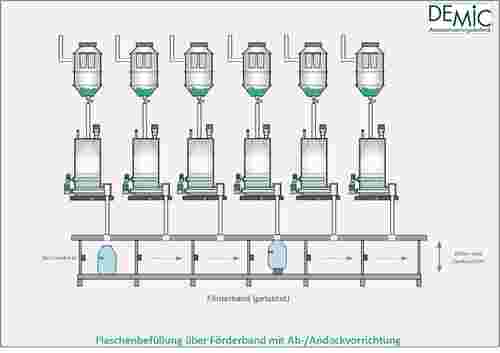

- Automation of all components of the refilling level with one control system

- Includes software modules for pneumatic conveying systems, bag chutes, BigBag stations, etc.

- 35 years of experience in refilling dosing equipment

- Industry 4.0-ready. Supports process data acquisition in the entire raw material supply chain

- Basis for preventive maintenance detection

- Provides accurate consumption reports and status information to MES/-ERP system

- Allows resource-saving startup and shutdown of plants

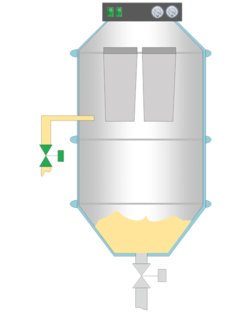

- Time- or event-controlled start of extraction and filter cleaning

- Pressure monitoring (underpressure, overpressure, differential pressure across filter)

- Control of discharge devices (vibrating bin discharger, screws, rotary valves, pushers)

- Fill level monitoring and filling lights

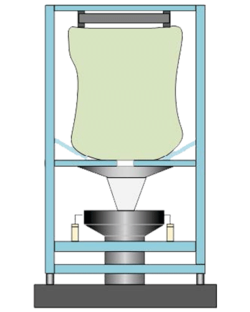

- Filling quantity detection and weighing via different load cell types

- Automatic feeding of containers

- Easy combination with pneumatic conveying system

- Time or cycle-based conveying cycles

- Pressure monitoring (negative pressure, positive pressure in suction system, differential pressure across filter) for predicitve maintenance

- Valve control in suction and clean air lines

- Level monitoring

- Air injection and pusher control as discharge aid

- Discharge flap (force control) incl. monitoring

- Adjustable discharge mode (partial discharge) for optimized start-up and shut-down

- Easy combination with dosing system or feeding station

Would you like to learn more about conveying and refilling?

We look forward to advising you:

PHONE: +49 2247 918 90

E-MAIL: kontakt(at)demic-datentechnik.de

Your contact

Björn Demmer

Shareholder - General manager

PHONE: +49 2247 918 90

E-MAIL: bdemmer(at)demic-datentechnik.de

Heinz Demmer

Shareholder - General manager

PHONE: +49 2247 918 90

E-MAIL: hdemmer(at)demic-datentechnik.de