Highlights

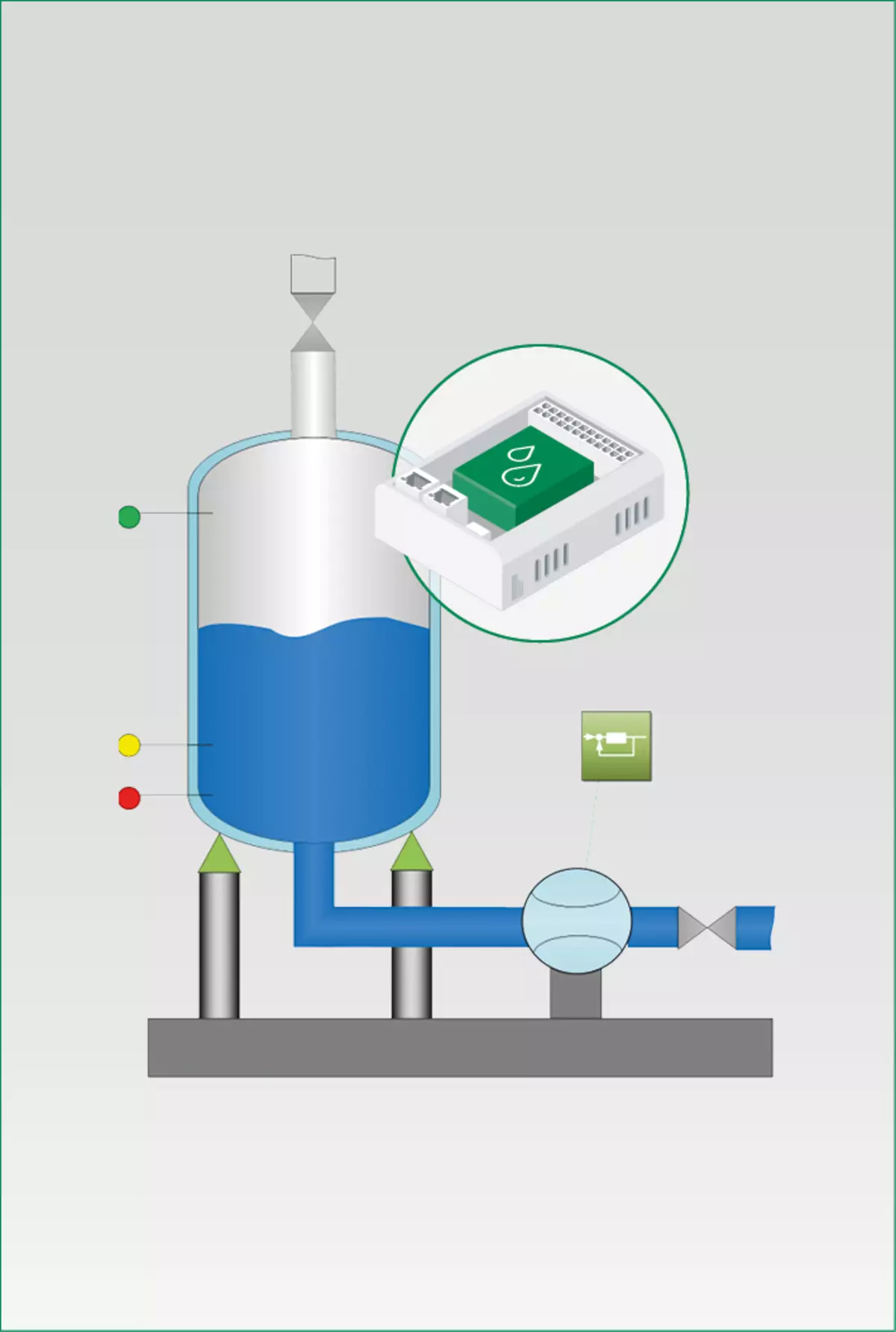

- Controls the setpoint-precise dosing according to the „Loss in Weight“ principle into a continuous process

- Supports the gravimetric and volumetric operation of differential feeders when dosing liquids

- Highly accurate dosing due to adaptive control

- Volume sensing flow meters (0/4-20 mA or frequency input)

- Pressure monitoring as actuator for the dosing elements (pumps or valves)

- Safety shutoff for gear pumps

- Level monitoring (min./max.) of an upstream hopper

- Digital filtering of the weight values ( detection digital / analog) for an exact calculation of the dosing capacity

- High-resolution filling quantity detection and weighing via digital/analog load cells

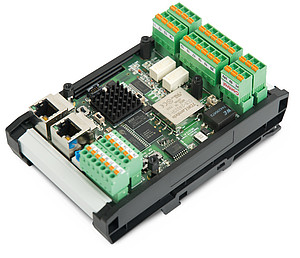

- Direct connection of load cells (4/6-wire technology)

Features

- Optimized refill handling

- Automatic scale calibration

- Speed monitoring of the discharge unit (digital / analog)

- Continuous performance determination and analysis for automatic performance adjustment in startup and shutdown mode

- Single and group operation

- Time-based throughput counters

- Control of the pump serial/analog

- Internal alarm buffer

- Integrated web server for complete configuration and parameterization

- Can be used in the control cabinet or directly in the plant

- 4 digital inputs/ and outputs with a number of standard functions (enable, operating contact, external fault, refill process, alarm, etc.) assignable or available for free use

Options

- Digital/Analog Extensions

- Operating Options

- DE-COP 5 single (for single operation of a dosing unit)

- DE-COP 5 multi (for operating up to 6 dosing units)

- DE-COP 16 (for operating up to 16 dosing units)

- Provis (Line software: up to 8 lines á 16 dosing units)

- AIO-Control (Plant visualization = dosing units + other devices)

Would you like to learn more about our products?

We look forward to advising you:

PHONE: +49 2247 918 90

E-MAIL: kontakt(at)demic-datentechnik.de

Your contact

Björn Demmer

Shareholder - General manager

PHONE: +49 2247 918 90

E-MAIL: bdemmer(at)demic-datentechnik.de

Heinz Demmer

Shareholder - General manager

PHONE: +49 2247 918 90

E-MAIL: hdemmer(at)demic-datentechnik.de