Batch-Weighing from DEMIC

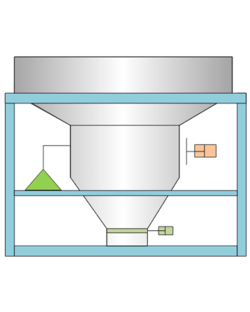

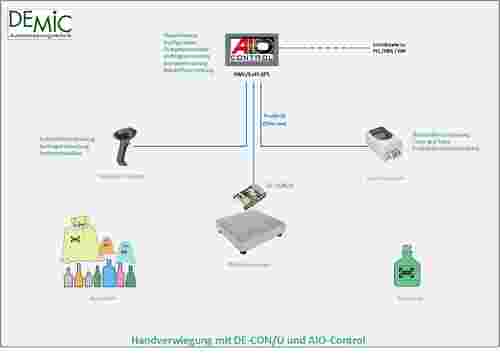

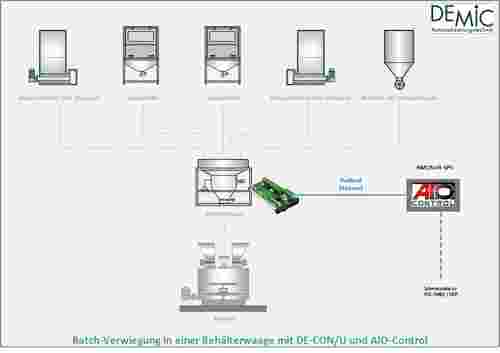

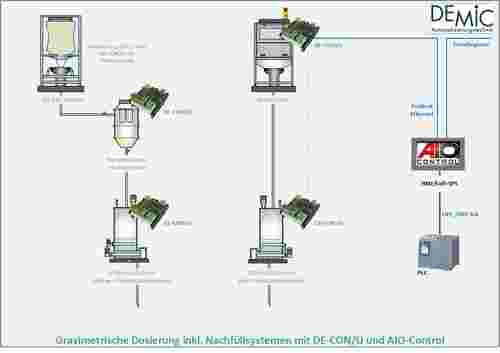

The controllers of the DE-CON/U family can also operate according to the "Gain-in-Weight" method and be used in automated batch processes, by simple configuration. Individual raw materials are added one after the other to a hopper/platform scale and processed by weighing via the control system. Using the same principle, complete raw material mixtures can also be produced due to recipe at a manual weighing station. The entire recipe control of a batch dosing and its detailed logging is carried out via the AIO-Control software and can be called up via interface after completion of a batch.

Individual solutions for batch weighing at

- Weighing controller for weighing bulk materials/raw materials according to the "Gain-in-Weight" method-Verfahren

- 35 years of experience with weighing systems (Brabender, Schenck, K-Tron,...)

- Weighing of smallest quantities up to several tons per batch

- Suitable for single and/or multiple component weighing

- High-resolution weight value acquisition via digital/analog load cells

- Digital filtering of synchronous and asynchronous disturbances

- Control of various discharge aids (e.g. beaters, unbalance motors, etc.) during the parameterizable discharge process

- Design of the devices for mounting in the control cabinet or directly on the machine (IP65)

- All device-specific parameters can be edited via the webserver

- Integrated control of refilling and conveying systems for optimal results

- Additional weight measurement (e.g. pre-container) possible via second load cell

- Filter cleaning and dust-tight docking systems integrated as standard

- Extensive range of interfaces for easy integration into automation landscape (Profinet, Profibus, Modbus, Ethernet IP, Serial)

- Function / communication blocks for TIA Portal freely available

- Can be excellently combined with AIO-Control for visualization on any PC and for recipe and order management incl. batch logging

- Application-related simulation/and test mode enables pre-tests and reduces time during commissioning

Would you like to learn more about batch weighing?

We look forward to advising you:

PHONE: +49 2247 918 90

E-MAIL: kontakt(at)demic-datentechnik.de

Your contact

Björn Demmer

Shareholder - General manager

PHONE: +49 2247 918 90

E-MAIL: bdemmer(at)demic-datentechnik.de

Heinz Demmer

Shareholder - General manager

PHONE: +49 2247 918 90

E-MAIL: hdemmer(at)demic-datentechnik.de